Slide Spot Robot

The Slide Spot Robot is an advanced automated welding system designed for precision spot welding applications. It features a robotic arm mounted on a linear slide, enabling it to reach multiple weld points across a wide work area—ideal for high-volume, repeatable tasks such as sheet metal panels and complex assemblies.

The system includes:

1. A spot welding gun

2. A sliding rail system for extended reach

3. Programmed weld paths for consistency and speed

4. Safety sensors and customizable programming options

These features ensure consistent weld quality, minimal variance, reduced operator intervention, and increased production efficiency.

My Role:

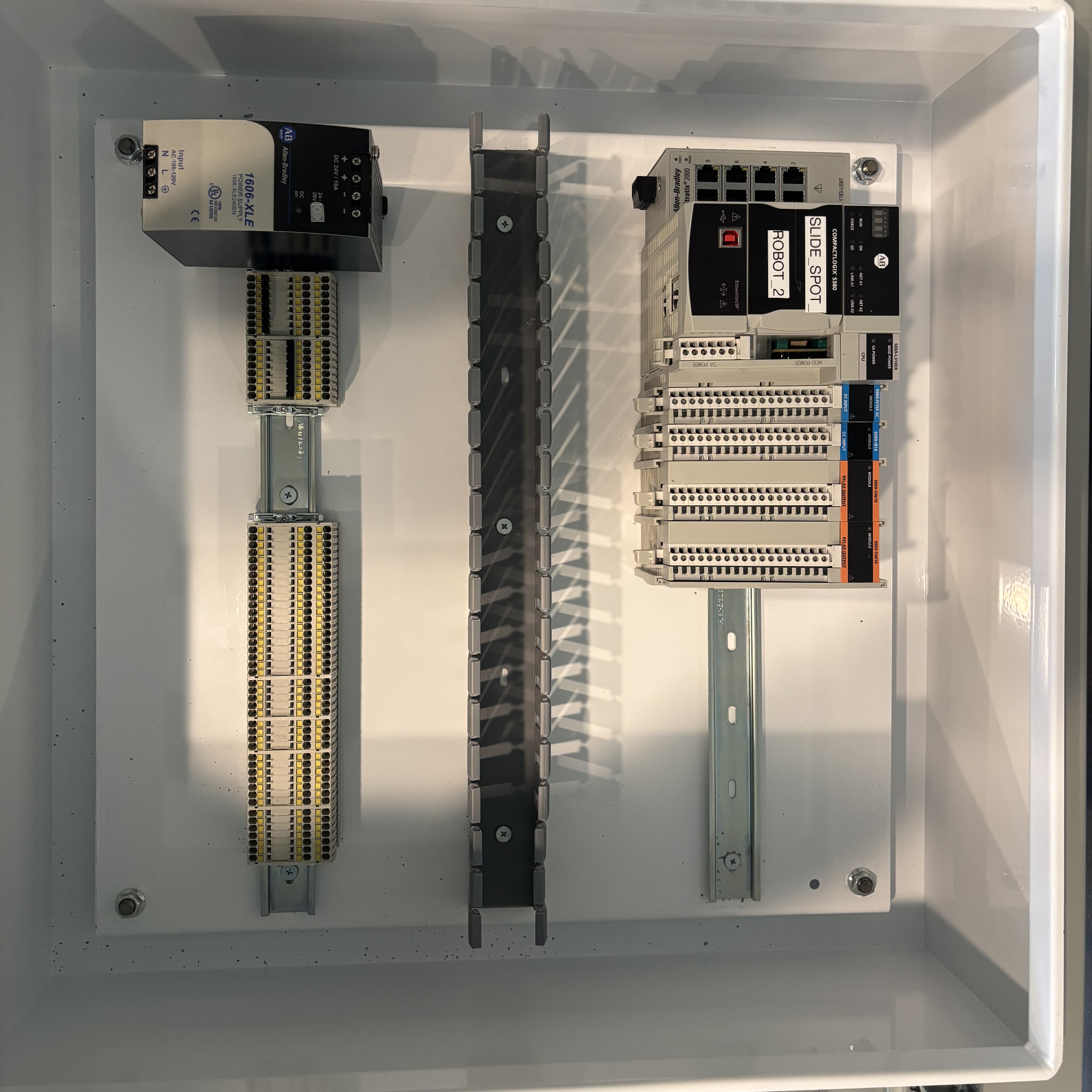

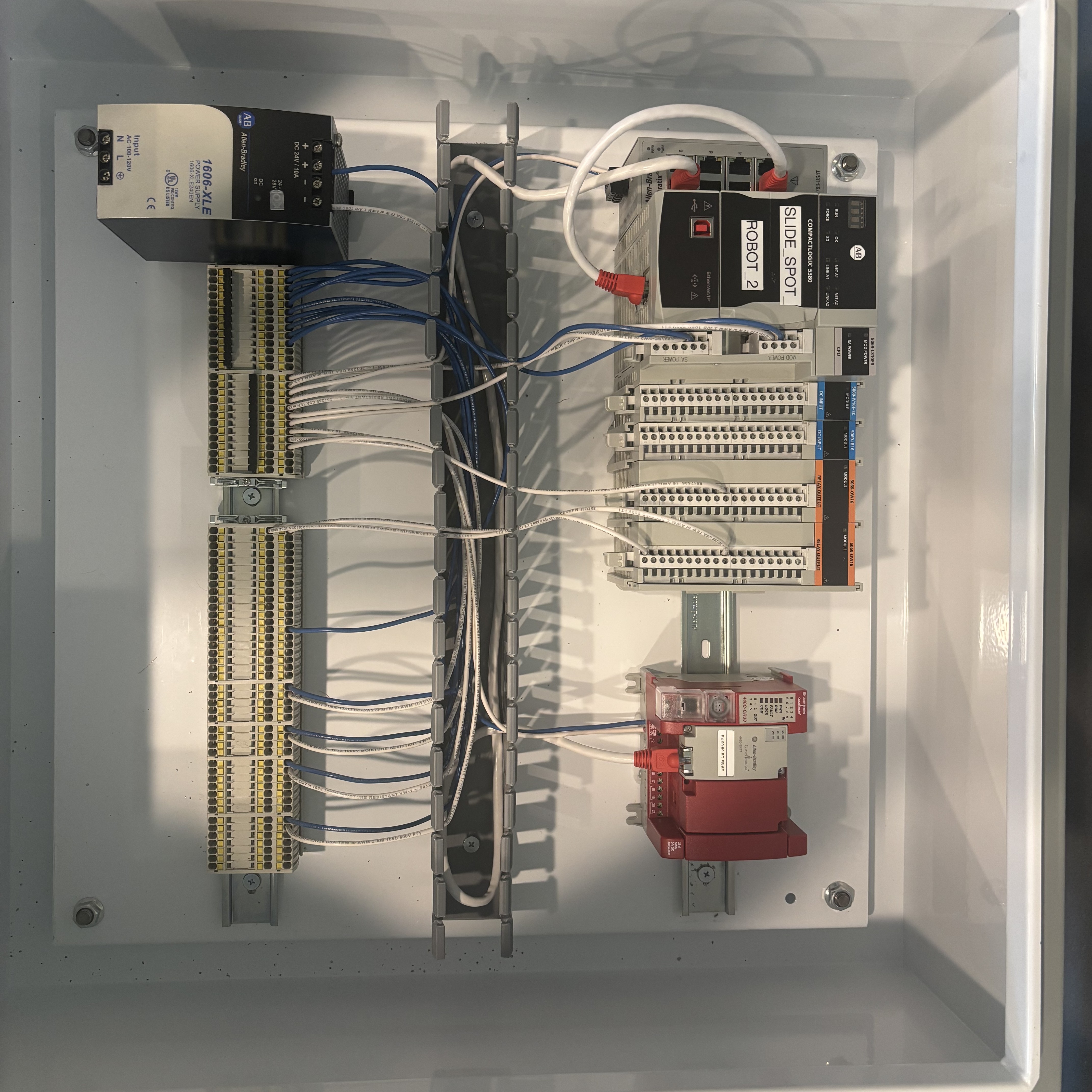

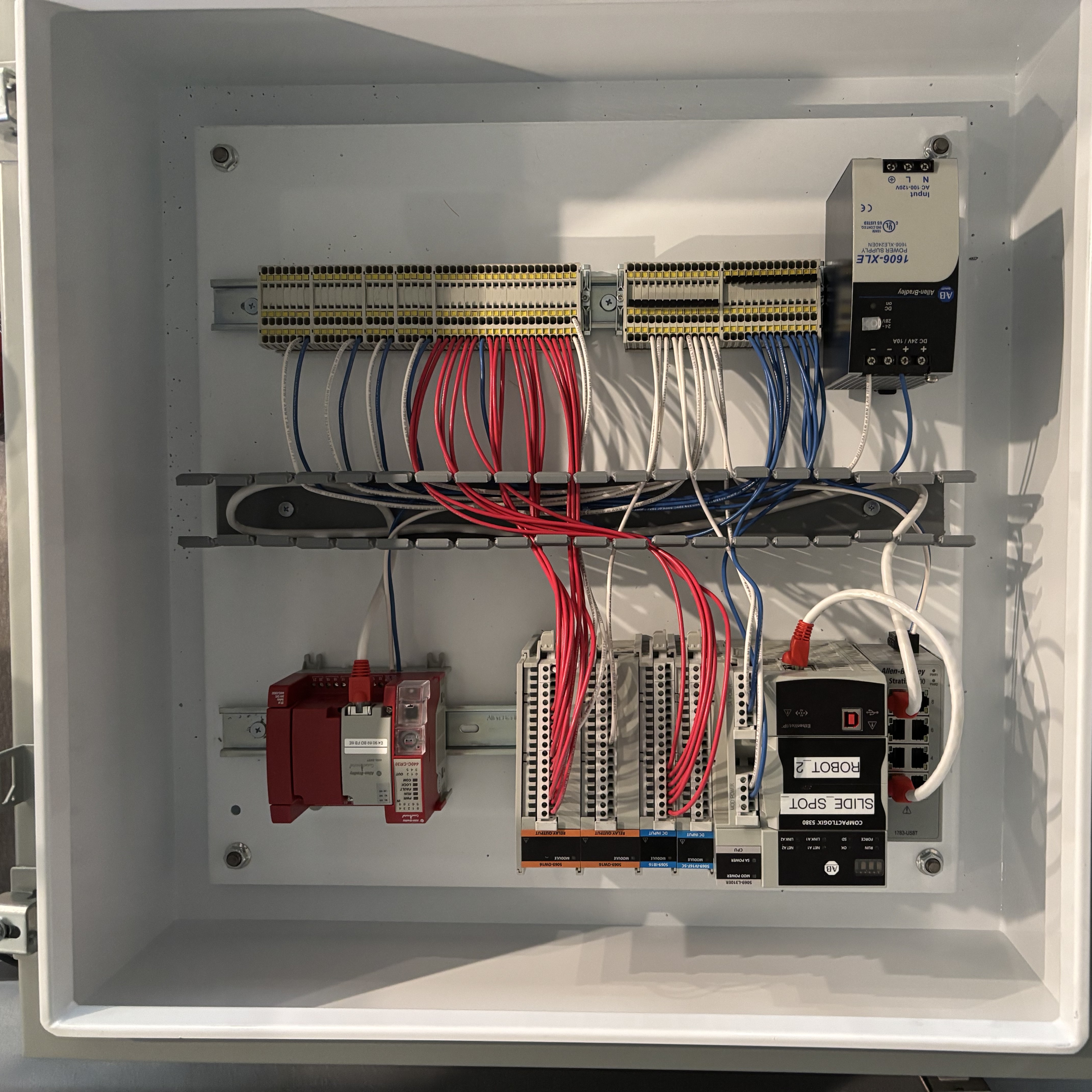

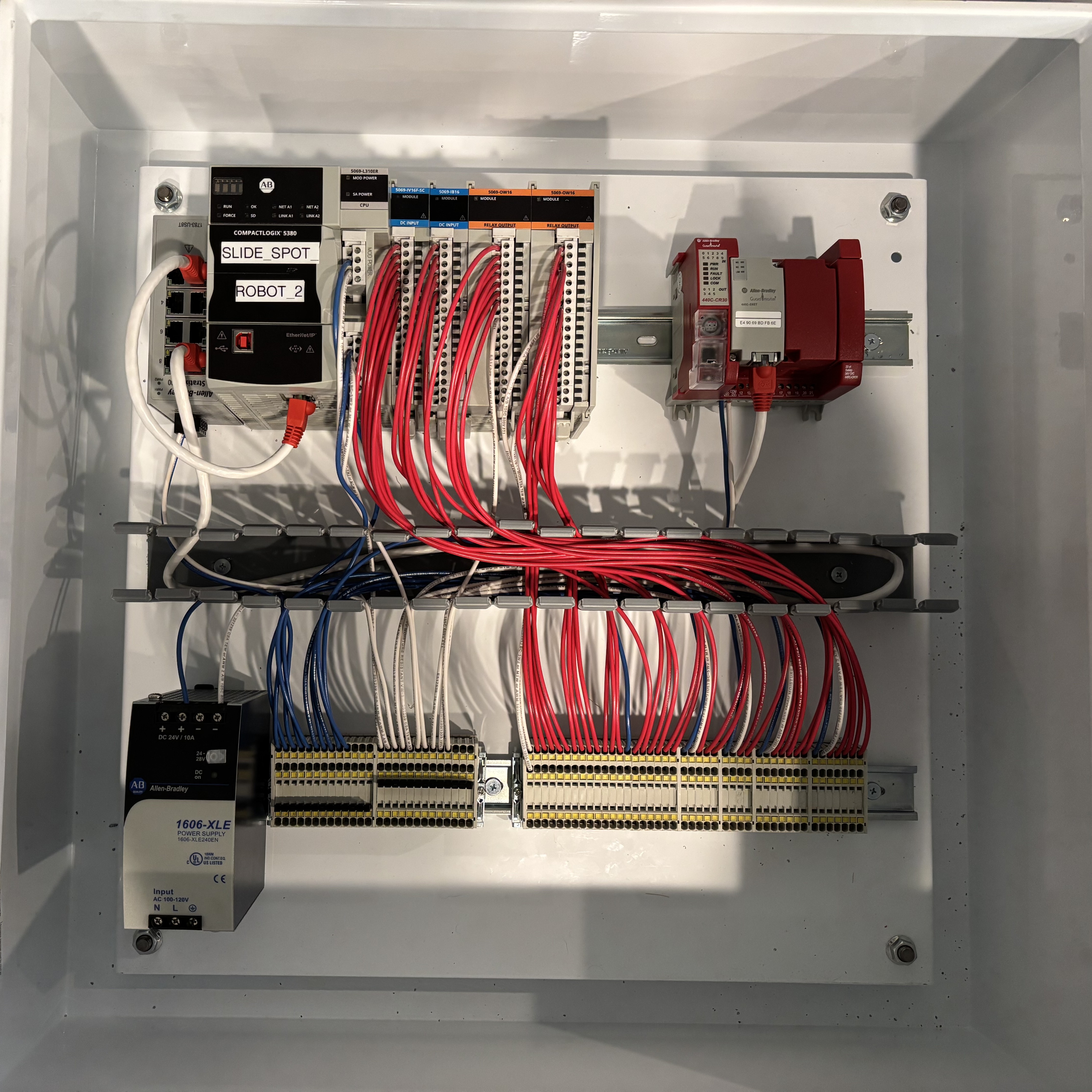

I was responsible for analyzing the wiring diagrams for two input cards, two output cards, and the welding control unit. I also reviewed the associated accessories, including gun holsters 1 and 2 and the welding tip cleaner. Based on this information, I reconstructed the electrical cabinet to restore the robot to full functionality. This cabinet housed the PLC, safety PLC, power supply, and terminal blocks, ensuring reliable operation and compliance with safety standards.

Technologies: Automation, Ladder Logic, PLC Programming, Electrical Wiring